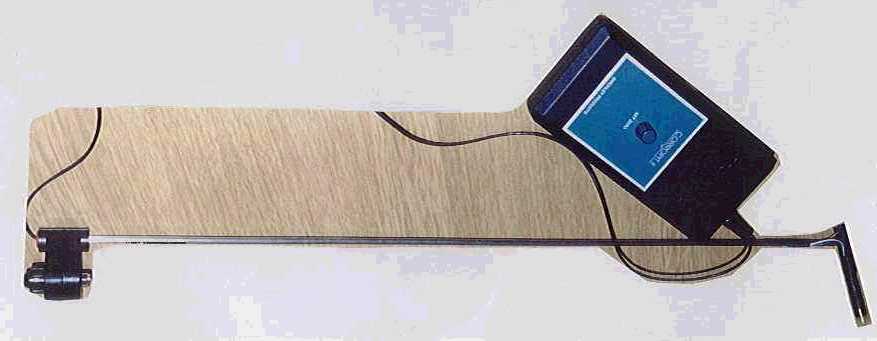

The Corropit device will measure the internal pits inside gas cylinders. The unit will fit through the BS341 .600" nom. Taper thread. (One of the smallest internal threads.)

A linear voltage differential transformer (LVDT) is placed on the end of a swivel mechanism. It moves from the vertical (to check the base) through 90o to a retro position of approx. 135o .

A needle probe is fitted on the end of the moveable

spindle of the LVDT, adjusted to the central or zero position. As the needle probe

enters the pit, under the action of a light spring, the central spindle of the LVDT alters

its position relative to the two coils. This reading is shown as millimetres on a

digital scale.

The unit is very accurate and entirely linear, it reads to .01mm, and to a depth of 6mm.

It will of course also measure any pits on the outside of the cylinder.

The unit can be made in various lengths to suit cylinder sizes.

The equipment is easily portable, and the standard model consists of a mains powered base

unit measuring approx. 190mm x 140mm x 65mm, the probe is detachable. The Corropit

unit is a break through in the measurement of internal pits in both aluminium and steel

constructed gas cylinders.

The unit may be altered either side of the vertical plane to measure depths of pits, that

do not go straight. (The unit may be felt into the pit and joggled around to find the

deepest point). The measurement is accurate and easily read on the LCD scale.

The zero may be finely adjusted. With very little practice accurate and

speedy identification of pit depths are measured.